Transec Electric

Transec's business focuses on the reliability of transformers – continuously removing water from the insulating oil of a power transformer.

Transec Electric story

Transec Electric is the new name for Transec UK Ltd. which was established over 15 years ago and since 2004 Transec has managed over 3350 Transformer On-Line Molecular Sieve Drying System projects worldwide.

Transec has supplied to over 20 countries including UK, China, India, Germany, South Korea, Australia, Saudi Arabia and Russia. UK installations have included UKPN, National Grid, SSE, Scottish Power, EDF Energy UK, EON, WPD and NPG.

Transec Electric Limited will continue to manufacture, support and develop Transformer On-Line Molecular Sieve Drying Systems and Services from its base in Haverhill, Suffolk., UK.

Transec has supplied to over 20 countries including UK, China, India, Germany, South Korea, Australia, Saudi Arabia and Russia. UK installations have included UKPN, National Grid, SSE, Scottish Power, EDF Energy UK, EON, WPD and NPG.

Transec Electric Limited will continue to manufacture, support and develop Transformer On-Line Molecular Sieve Drying Systems and Services from its base in Haverhill, Suffolk., UK.

About technology

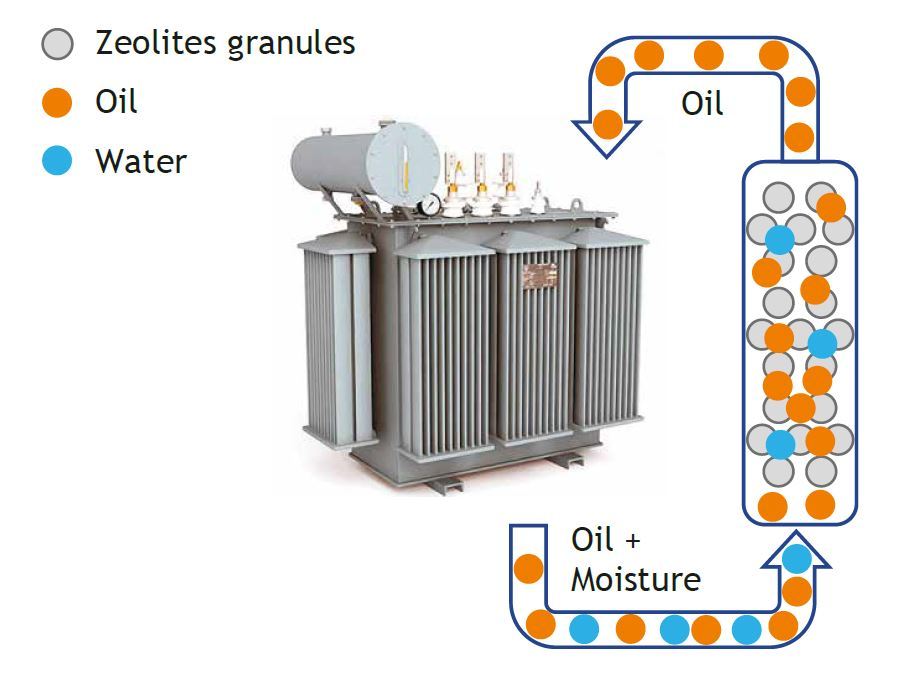

Since the beginning, Transec's business has been focused on the reliability of transformers, with one of the most important features – continuously removing water from the insulating oil of a power transformer.

Why is it so important?

Power and distribution transformers are some of the most important and expensive assets in a power network. Compared to other equipment, they are very reliable and require very little maintenance since they have no continuously moving parts. However, the insulating materials, being organic, degrade with time in service, and ultimately determine the end of life of the transformer.

In a poorly maintained free breathing transformer water can enter through the natural expansion and contraction of oil as the temperature cycles, but also water is a by-product of the breakdown of the long chain hydro- carbon glucose molecule, as a result of thermal and electrical stress. This leads to degradation of the organic insulation materials as the transformer ages.

Excessive moisture will saturate the insulation and increase its conductivity. At higher temperatures, vapour or free moisture can develop increasing the risk of partial discharge.

TRANSEC is an online molecular sieve, developed and manufactured in the U.K. that is designed to continuously remove water from the insulating oil of a power transformer. As the ppm level in the oil is reduced, water from the solid insulation (where over 95% of the water will accumulate) will migrate from the insulation into the oil to redress the natural equilibrium. This process not only reduces ageing, but will improve the dielectric strength of the insulation, and increase reliability.

Why is it so important?

Power and distribution transformers are some of the most important and expensive assets in a power network. Compared to other equipment, they are very reliable and require very little maintenance since they have no continuously moving parts. However, the insulating materials, being organic, degrade with time in service, and ultimately determine the end of life of the transformer.

In a poorly maintained free breathing transformer water can enter through the natural expansion and contraction of oil as the temperature cycles, but also water is a by-product of the breakdown of the long chain hydro- carbon glucose molecule, as a result of thermal and electrical stress. This leads to degradation of the organic insulation materials as the transformer ages.

Excessive moisture will saturate the insulation and increase its conductivity. At higher temperatures, vapour or free moisture can develop increasing the risk of partial discharge.

TRANSEC is an online molecular sieve, developed and manufactured in the U.K. that is designed to continuously remove water from the insulating oil of a power transformer. As the ppm level in the oil is reduced, water from the solid insulation (where over 95% of the water will accumulate) will migrate from the insulation into the oil to redress the natural equilibrium. This process not only reduces ageing, but will improve the dielectric strength of the insulation, and increase reliability.

Products

• high capacity for moisture extraction (12 litre)

• for transformer >10 MVA

• long operation duration without maintenance

• in frame or in cabinet

• measuring and monitoring module available

CL3A

• low weight, easy to move

• for transformer <10 MVA

• cost effective and flexible to operate on different transformer

• measuring and monitoring module available

CL1A

Products

• high capacity for moisture extraction (12 litre)

• for transformer >10 MVA

• long operation duration without maintenance

• in frame or in cabinet

• measuring and monitoring module available

CL3A

• low weight, easy to move

• for transformer <10 MVA

• cost effective and flexible to operate on different transformer

• measuring and monitoring module available

CL1A

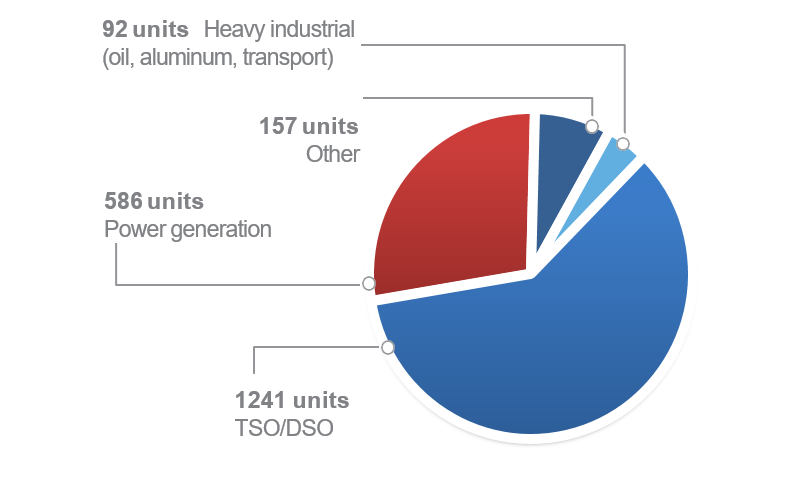

Experience

2076 units installed

22 countries

22 countries

End user business profile

Cylinder regeneration

TRANSEC cylinders can typically extract between 3 to 4 liters of water. The extraction speed is directly linked to the amount of water available in the transformer. The more water is available and the warmer the oil is, faster the extraction will be. You can find typical saturation time below.

The cylinder saturation can be determined either by the TRANSEC monitoring system or by comparing water PPM in 2 oil samples (inlet & outlet).

Saturated cylinders can be removed and replaced online by new ones within 30 min. A stock of ready cylinders is always available locally with our partners.

The cylinder saturation can be determined either by the TRANSEC monitoring system or by comparing water PPM in 2 oil samples (inlet & outlet).

Saturated cylinders can be removed and replaced online by new ones within 30 min. A stock of ready cylinders is always available locally with our partners.

Installations' examples

Installations' examples

- Transec in ChileJuly 2019The power of the company's' transformer is 30 mVA. In view of the insulation humidity issues, the transformer is in pre-accident condition, although it has been used for not so long. This is due to the fact that high air humidity is typical for the Chile region.

The average results of the transformer state analysis have shown approximately 3.4% moisture content in its insulation. With reference to the volume, it equals about 52.4 liters of conductive fluid. Transec measurement data - 34 ppm of water in oil at the inlet, 0 ppm after drying. Two representatives of the Streamer distributor in Chile were assembling the equipment. Installation, commissioning and start-up took about 3 hours. - JSC Petrostal Metallurgical PlantSeptember 2019The insulation drying process was performed on the transformer UTMRU 3500/35 in the period of August 21 to 23, 2019. The transformer was running for the entire period of service to provide the power supply to a rolling mill. The efficiency of the Transec unit was confirmed by a humidity monitoring system installed on the transformer and also by the transformer oil testing which has demonstrated a reduction in the oil humidity from 37 to 17 g/T. The dielectric properties of the oil were also improved. With regard to its physical and chemical parameters, it has achieved a full compliance with the requirements of the RD 34.45-51.300-97. The company representatives point out safety and reliability of the unit operation: the insulation drying process was performed continuously and unattended on the running transformer; no oil leakages occurred; the system tightness was confirmed by an absence of actuations of the gas protection.

- The Chihuahua III gas power plantFebruary 2019Transec system installed at the Chihuahua III gas power plant located close to Ciudad Juárez, a city almost bordering the United States.

Chihuahua III is an important facility of the InterGen Company generating system. Its design capacity is 271 MW, the power plant itself comprises of three units.

The transformer capacity is 150 MVA, the oil volume is 54 cubic meters.

A Transec system installation took place in severe conditions. The base of the transformer was surrounded by gravel, unstable soil, not suitable to be a foundation for anything. Our experts had therefore developed a unique mounting system on-site for Transec equipment that involved the transformer construction features. They also calibrated the power supply system for correct operation.

Transec in Chile

The power of the company's' transformer is 30 mVA. In view of the insulation humidity issues, the transformer is in pre-accident condition, although it has been used for not so long. This is due to the fact that high air humidity is typical for the Chile region.

The average results of the transformer state analysis have shown approximately 3.4% moisture content in its insulation. With reference to the volume, it equals about 52.4 liters of conductive fluid. Transec measurement data - 34 ppm of water in oil at the inlet, 0 ppm after drying. Two representatives of the Streamer distributor in Chile were assembling the equipment. Installation, commissioning and start-up took about 3 hours.

The average results of the transformer state analysis have shown approximately 3.4% moisture content in its insulation. With reference to the volume, it equals about 52.4 liters of conductive fluid. Transec measurement data - 34 ppm of water in oil at the inlet, 0 ppm after drying. Two representatives of the Streamer distributor in Chile were assembling the equipment. Installation, commissioning and start-up took about 3 hours.

JSC Petrostal Metallurgical Plant

The insulation drying process was performed on the transformer UTMRU 3500/35 in the period of August 21 to 23, 2019. The transformer was running for the entire period of service to provide the power supply to a rolling mill. The efficiency of the Transec unit was confirmed by a humidity monitoring system installed on the transformer and also by the transformer oil testing which has demonstrated a reduction in the oil humidity from 37 to 17 g/T. The dielectric properties of the oil were also improved. With regard to its physical and chemical parameters, it has achieved a full compliance with the requirements of the RD 34.45-51.300-97. The company representatives point out safety and reliability of the unit operation: the insulation drying process was performed continuously and unattended on the running transformer; no oil leakages occurred; the system tightness was confirmed by an absence of actuations of the gas protection.

The Chihuahua III gas power plant

Transec system installed at the Chihuahua III gas power plant located close to Ciudad Juárez, a city almost bordering the United States.

Chihuahua III is an important facility of the InterGen Company generating system. Its design capacity is 271 MW, the power plant itself comprises of three units.

The transformer capacity is 150 MVA, the oil volume is 54 cubic meters.

A Transec system installation took place in severe conditions. The base of the transformer was surrounded by gravel, unstable soil, not suitable to be a foundation for anything. Our experts had therefore developed a unique mounting system on-site for Transec equipment that involved the transformer construction features. They also calibrated the power supply system for correct operation.

Chihuahua III is an important facility of the InterGen Company generating system. Its design capacity is 271 MW, the power plant itself comprises of three units.

The transformer capacity is 150 MVA, the oil volume is 54 cubic meters.

A Transec system installation took place in severe conditions. The base of the transformer was surrounded by gravel, unstable soil, not suitable to be a foundation for anything. Our experts had therefore developed a unique mounting system on-site for Transec equipment that involved the transformer construction features. They also calibrated the power supply system for correct operation.

Why are we better

- Increases life expectancy of Transformers

- Drying Transformer continuously during operation

- Easy Transformer maintenance without outage

© All Rights Reserved. Transec Electric Ltd. 11617682

Email: ian.litllewood@tr-electric.uk

51 Hollands Road Haverhill, Suffolk CB9 8PL. UK

Email: ian.litllewood@tr-electric.uk

51 Hollands Road Haverhill, Suffolk CB9 8PL. UK